The 2025 Curtiss 1

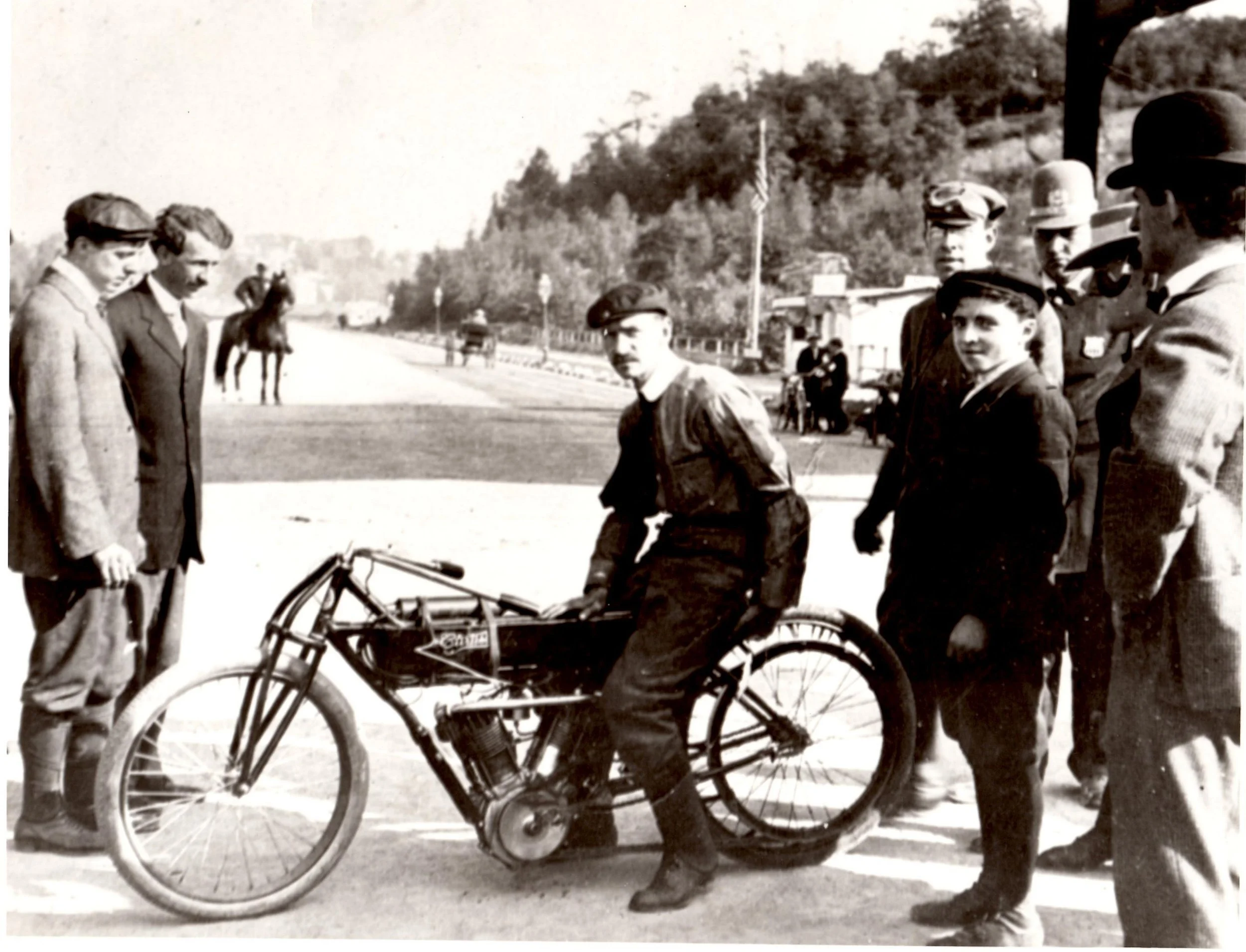

At the beginning, when the future was all that mattered and technological progress was measured in months, not years, we find our inspiration. In 1902, Glenn Curtiss built his first production motorcycle. Within five years he had achieved a world speed record of 136 miles per hour. As we enter fully into the 21st century, we encounter a similar nexus, a second Industrial Cambrian Explosion. For our own journey, 120+ years later, it’s his passion that still has value and informs our process.

Rather than being merely a pastiche of clumsily applied vintage motorcycle styling cues, our goal has been to create a new motorcycle that is culturally and contextually relevant. We seek understanding of what the ancients got right, what they got wrong, and what they did not yet know. To this end, an appreciation and sensitivity to the past, without a prostration to it, carries a responsibility to innovate.

Because the gestation period has been fluid, our team has had the luxury of front-loading the underlying engineering work. Getting things “right” the first time is the logical result when passion and experience intersect, both of which are on hand with our team. Therefore, we have arrived at the precipice of a series production motorcycle that simultaneously predicts and shapes the future we desire....

Our design objectives for The Curtiss 1 fall into seven main categories: Innovation, Suspension, Ergonomics, CMF, Quality, Design Language, and Economy.

Innovation

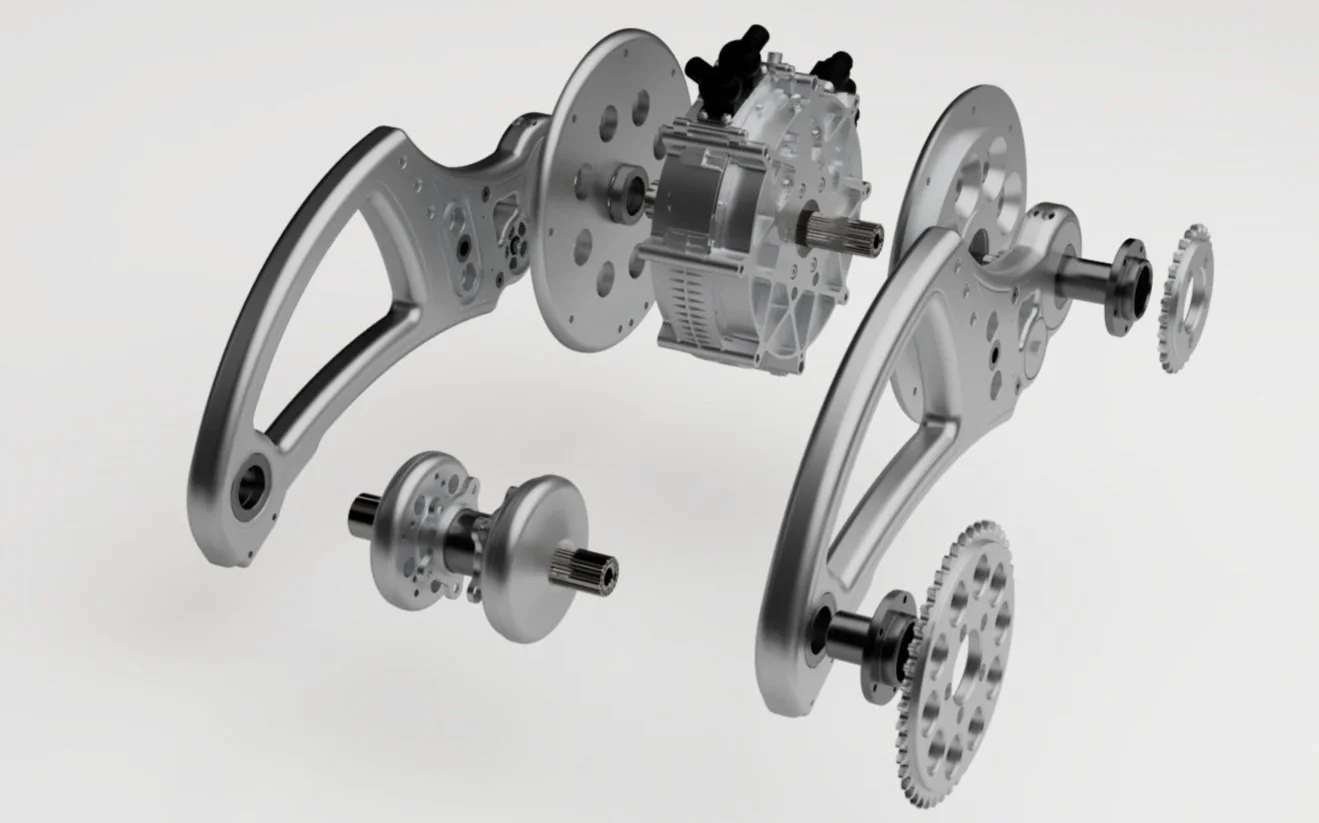

Our patent-pending Curtiss Centered Power Axis uses the strongest part of the motorcycle, the massive splined hard-steel axle, to perform two key functions. It serves as the drive shaft of the electric drivetrain adding outer-bearing support surface area and the swing arm pivot at the same time. This proprietary solution offers part-count reduction and ease- of-assembly. The design also eliminates a weak stub-axle swing arm pivot, providing strength and longevity to the design. Splined drive plates perform double-duty, front and rear, providing bearing surfaces on the drive-side of the system.

Suspension

Curtiss motorcycles are battery electric. The lack of an internal combustion engine creates a noise-free environment for a pure riding experience. Lack of vibration and unnecessary dedicated cognitive space to modulate an ICE means that road feel will be unmasked and unfiltered, compelling us to re-examine the status quo.

Motorcycle suspension has been a process of refinement post-WWII with telescopic fluid-filled front fork tubes and coil-over rear shock arrangement. The modern motorcycle with its highly refined version of this system has proven the validity of this formula, but we submit that it has done little to address its underlying weaknesses. Those being:

Stiction - The reliance on bushings within the telescoping elements to provide free play between the two causes minute pauses in motion, especially in directional changes from rebound to compression.

Torsional Rigidity - Fork tubes are prone to twisting forces, and rely entirely on the front axle attachment points to counteract twisting around the steering axis.

Wheel Trajectory Control - The critical relationship between steering neck angle (rake) and front wheel contact patch yields the trail value. With a linear front fork (deflection not withstanding), trail values will always have a non-alterable trail curve to suspension travel ratio when graphed.

Dive - Applying force to front wheel brake discs results in a high degree of compression of the front fork tubes as the entire mass of the motorcycle and rider now pivots around the abruptly introduced pole of moments around the front axle. Weight transfer vectors greatly reduce the effectiveness of the front suspension by asking the springs to suspend, while concurrently resist deceleration forces.

Mass Centralization - Two front fork tubes filled with fluid and springs, positioned far from the steering axis resist quick directional changes.

Un-sprung Weight - All fluid within the front fork tubes is considered un-sprung, as is a large percentage of the heavy steel coil spring and valving that travels with the wheels.

Longevity - As any motorcycle restoration expert will attest, the first thing that typically fails on a motorcycle are the fork tube seals. The underlying premise of a large diameter linear seal is inherently flawed.

Our exploration begins with a look into the past. Currently regarded as an anachronism, the girder-style front fork does have advantages, especially with the application of modern materials, bearing surfaces, and fully understood geometries. Pushing further into possibility, the unification of the two halves of the girder via a cross brace into a single piece both increases rigidity and reduces complexity. Narrowing the frontal area of a motorcycle is germane to the fundamentals of motorcycle aerodynamics and efficiencies at speed.

Stiction can be greatly reduced with the use of a multi-link front fork that does not rely on isolating bushings for the tubes to telescope smoothly, or rake angles to counter deflection of those tubes as they vector impact forces from irregularities in the road surface to the chassis. Multi-link front suspension systems have inherent torsional rigidity, and when properly tuned, are inherently anti-dive as the loads applied during braking are not transferred directly to the chassis through the spring.

The true benefit of a multi-link type front suspension lies in front wheel trajectories that can be altered by varying length and placement of the connecting links with eccentrics. This trail value fine tuning has the advantage of altering trail values for any given suspension or rake angle setting. Expressed as a graph, more or less trail can be achieved for any given suspension compression value, as desired, without the constraints of a linear telescoping front fork. Ideally, the graph will yield an initial scrubbing off of trail within the first half of suspension travel, and then a leveling and stabilization of the trail value throughout the remainder of travel. The “feel” of maneuverability with reduced trail will be maintained, without the exponential loss of stability.